Payment Type:T/T,Paypal

Incoterm:FOB,EXW

Transportation:Ocean,Air

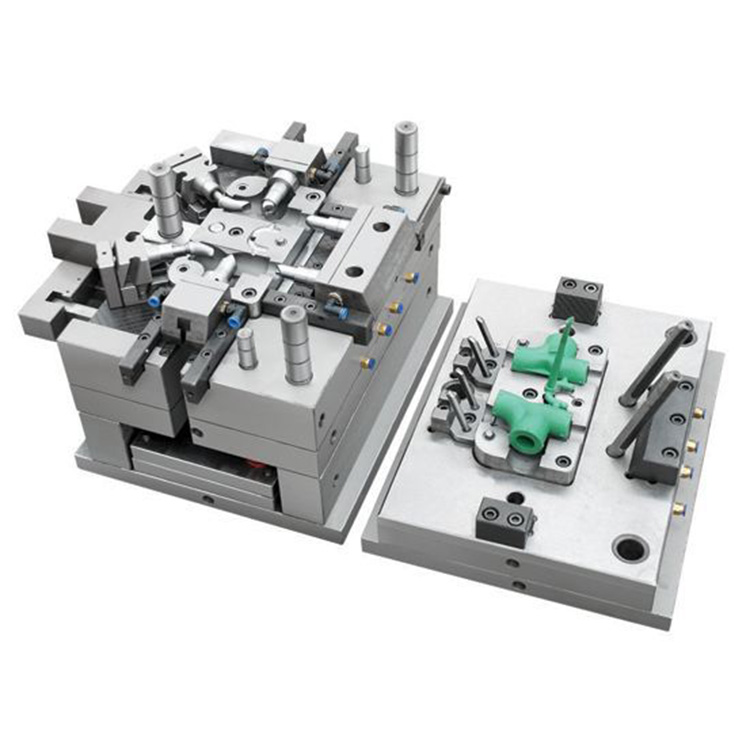

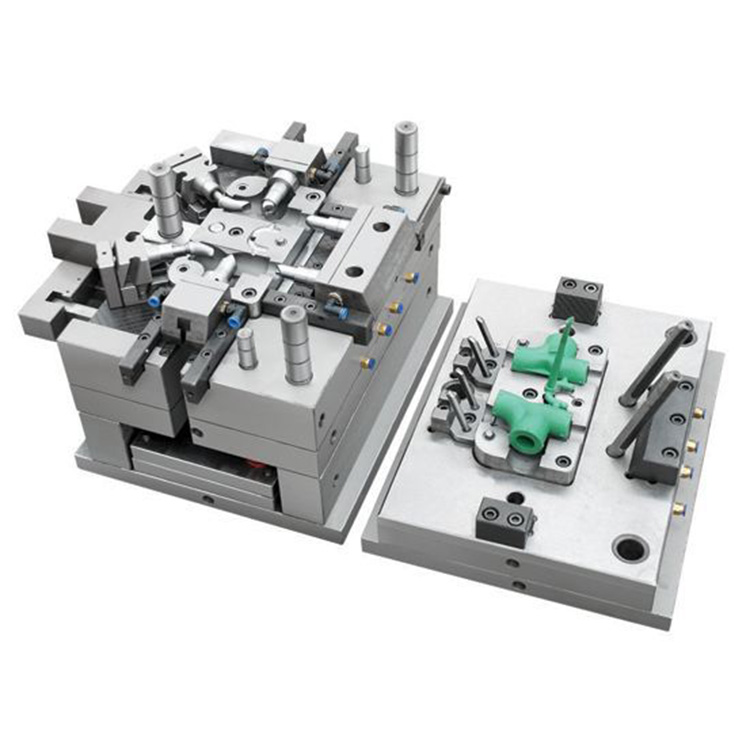

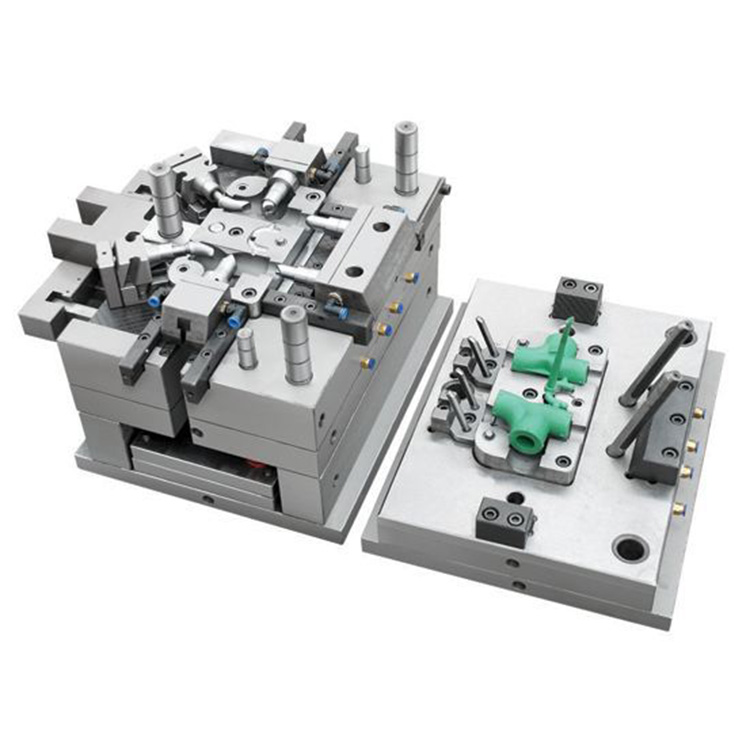

Model No.: AD-102

Brand: AD-267

Forming Method: Plastic Injection Mould, Preform Mould, Extrusion Mould

Product Material: Plastic

Transportation: Ocean,Air

Payment Type: T/T,Paypal

Incoterm: FOB,EXW