Office Equipment Mold

(Total 10 Products)-

Brand:AD-063Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthPrinter/copier plastic shell mold Dongguan Anding Technology Manufacturing Co., Ltd. is a modern private enterprise integrating product development and design, precision mold manufacturing, product injection molding, oil injection screen printing,...

-

Brand:AD-067Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthoffice chair plastic shell mold Dongguan Anding Technology Manufacturing Co., Ltd. is a modern private enterprise integrating product development and design, precision mold manufacturing, product injection molding, oil injection screen printing, and...

-

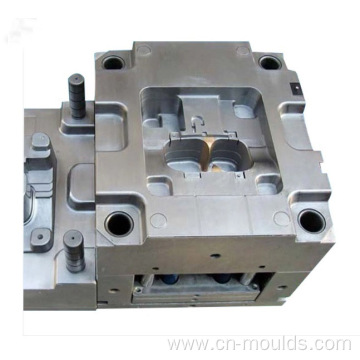

Brand:AD-068Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOffice Equipment Plastic Shell Mold Dongguan Anding Technology Manufacturing Co., Ltd. is a modern private enterprise integrating product development and design, precision mold manufacturing, product injection molding, oil injection screen printing,...

-

Brand:AD-004Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOffice Equipment Plastic Shell Mold We mainly produce household appliances, digital, communication, office, computer, network and other precision plastics. Through case cooperation with different customers with different requirements, different...

-

Brand:AD-005Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOffice Equipment Plastic Shell Mold We mainly produce household appliances, digital, communication, office, computer, network and other precision plastics. Through case cooperation with different customers with different requirements, different...

-

Brand:AD-006Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOffice Equipment Plastic Shell Mold Dongguan Anding Technology Manufacturing Co., Ltd. is a modern private enterprise integrating product development and design, precision mold manufacturing, product injection molding, oil injection screen printing,...

-

Brand:AD-008Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOffice Equipment Plastic Shell Mold:Mould for office telephone We mainly produce household appliances, digital, communication, office, computer, network and other precision plastics. Through case cooperation with different customers with different...

-

Brand:AD-009Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOffice Equipment Plastic Shell Mold We mainly produce household appliances, digital, communication, office, computer, network and other precision plastics. Through case cooperation with different customers with different requirements, different...

-

Brand:AD-088Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOffice Equipment Plastic Shell Mold:Mould for office telephone We mainly produce household appliances, digital, communication, office, computer, network and other precision plastics. Through case cooperation with different customers with different...

-

Brand:AD-077Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthComputer monitor plastic shell mold/Plastic mould for display case Dongguan Anding Technology Manufacturing Co., Ltd. is a modern private enterprise integrating product development and design, precision mold manufacturing, product injection molding,...

Office Equipment Mold,Office Equipment Moulds,Office Supplies Molds,Company office supplies molds

About Us

We mainly produce household appliances, digital, communication, office, computer, network and other precision plastics. Through case cooperation with different customers with different requirements, different models of Hot runner systems are used to process and manufacture molds. At the same time, various cutting-edge technologies such as ultra precision molds, IMD/IML are vigorously developed to increase the company's competitive advantage in technology. Home appliances are mainly PHILIPS, Toshiba, Hitachi, etc., remote control series are mainly Asus, Haier, Helian, Wanshiyi, etc., as well as office equipment product series.

FAQ

1.

What are the precautions for mold maintenance

Precautions for mold maintenance:1. When disassembling the mold, avoid scratches and dripping water, and move smoothly.2. Spray hot mold and then spray a small amount of release agent3. It is necessary to conduct a comprehensive inspection of the mold and carry out rust prevention treatment: carefully dry the moisture and debris in the cavity, core, ejection mechanism, and line position, and spray the mold rust inhibitor and apply butter.

2.

What are the precautions for mold maintenance

Maintenance of moldsDuring the continuous working process of the mold, it is easy to cause wear and tear of components, deterioration of lubricants, water leakage, and pressure damage of plastic materials during movement. Therefore, mold maintenance is necessary.1. Regular rust removal (appearance, PL surface, mold cavity, core, etc.)2. Regularly reapply lubricant (ejection mechanism, travel position, etc.)3. Regularly replace easily worn parts (pull rods, bolts, etc.)4. Other areas that need to be noted

3.

Stripe problem during injection molding processing

During the processing of injection molded parts, it is necessary to correctly plan and reasonably layout the diversion holes, determine the length of the working strip and the transition of length changes, as well as ensure that the mold bridge is in a dripping shape and has a reasonable welding angle. By placing the welding point on the plane of the welding chamber and ensuring the rigidity and strength of the mold core, deepening the depth of the welding chamber or expanding the cross-sectional area of the welding chamber, a "sinking bridge" is selected when necessary as a basic method to avoid the appearance of stripe defects.Proper planning of the injection molding process is the foundation for ensuring product quality. Reasonable layout of diversion holes can ensure uniform distribution of molten plastic during injection into the mold, avoid uneven flow, and thus reduce the generation of stripes. The determination of the length of the work strip and the transition of length changes can ensure the stability of the injection molded parts during the processing, and avoid the occurrence of adverse deformation and stripes.

4.

What materials are mainly used for automotive parts molds

The urea box injection molding accessories in automotive parts injection molding mainly use PA66+30% GF. The most prominent feature of PA66 raw material in the polyamide family is its high melting point. As it is a semi crystalline material, even under high temperature conditions, PA66 still has high strength and rigidity. However, the water absorption of nylon still exists even after it is made into a finished product, and the degree of water absorption in the later stage depends on wall thickness and usage conditions, So when designing precision components, it is necessary to fully consider the impact of PA66+30% GF material due to its hygroscopicity. Due to the defects of pure raw materials, other materials or additives are usually added to improve their mechanical properties, such as glass fiber reinforcement. Therefore, this material is widely used in automotive parts injection molding products.