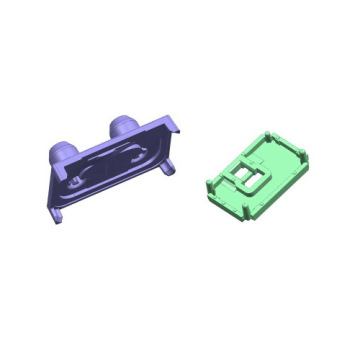

Electronic Digital Product Mold

(Total 8 Products)-

Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOur company adheres to the corporate tenet of "emphasis on quality, integrity, and responsibility", with the business philosophy of "customer first, technology, efficiency, and service". Under the guidance of the "Four Fines" business policy, the...

-

Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthWe mainly produce household appliances, digital, communication, office, computer, network and other precision plastics. Through case cooperation with different customers with different requirements, different models of Hot runner systems are used to...

-

Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOur company adheres to the corporate tenet of "emphasis on quality, integrity, and responsibility", with the business philosophy of "customer first, technology, efficiency, and service". Under the guidance of the "Four Fines" business policy, the...

-

Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOur company adheres to the corporate tenet of "emphasis on quality, integrity, and responsibility", with the business philosophy of "customer first, technology, efficiency, and service". Under the guidance of the "Four Fines" business policy, the...

-

Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOur company adheres to the corporate tenet of "emphasis on quality, integrity, and responsibility", with the business philosophy of "customer first, technology, efficiency, and service". Under the guidance of the "Four Fines" business policy, the...

-

Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthOur company adheres to the corporate tenet of "emphasis on quality, integrity, and responsibility", with the business philosophy of "customer first, technology, efficiency, and service". Under the guidance of the "Four Fines" business policy, the...

-

Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthPlace of Origin:DongguanDongguan Anding Technology Manufacturing Co., Ltd. is located in Chuangye Road, Dongshan Village, Qishi Town, Dongguan City, with convenient transportation. Our company adheres to the corporate tenet of "emphasis on quality, integrity, and...

-

Transportation:Ocean,Land,Air,ExpressPackaging:Wooden or cardboard boxesSupply Ability:60 sets/monthPlace of Origin:DongguanOur company adheres to the corporate tenet of "emphasis on quality, integrity, and responsibility", with the business philosophy of "customer first, technology, efficiency, and service". Under the guidance of the "Four Fines" business policy, the...

Electronic product mold,Electronic Digital Product Mold,Electronic Product Moulds,Electronic Product Molds,lectronic Digital Product Moulds

FAQ

Basic Overview of Automotive Moulds

The main component of Auto parts moulds is

the cover mold. These types of molds are mainly cold stamping molds. In

a broad sense, "automobile molds" are the general term for molds used

to manufacture all parts of automobiles.

1. Auto parts moulds are the general term for molds used to manufacture all parts of automobiles.

2. Automotive stamping molds are molds used to punch all stamping parts on automobiles.

3. The automobile body stamping mold is a mold used to punch all stamping parts on the automobile body.

4. The stamping mold for automotive panels is a mold for punching all the panels on the vehicle body.

Plastic mold is a combination mold used

for compression molding, extrusion molding, Injection mold processing,

blow molding, and low foam molding.

Injection molding, also known as injection molding

Injection mold processing(Plastic shell

mold), also known as injection molding, is a molding method that

involves both injection and molding. The advantages of injection molding

method are fast production speed, high efficiency, automated operation,

multiple varieties of designs, shapes that can be simplified to

complex, and sizes that can be large to small. Moreover, the product

size is accurate, the product is easy to update and replace, and can

form complex shaped parts. Injection molding(Injection mold for pipe

fittings) is suitable for mass production and complex shaped products

and other molding processing fields.

A method of obtaining a molded product by

stirring fully melted plastic material with a screw at a certain

temperature, injecting it into the mold cavity under high pressure, and

cooling and curing it. This method is suitable for mass production of

complex shaped components and is one of the important processing

methods.

Mold processing process,Injection mold processing

Mold processing-Injection mold processing,plastic injection mould

Material opening: front mold material, rear mold material, insert material, row position material, and inclined top material;

Opening frame: front mold frame, Plastic mold;

Opening thickness: opening thickness of

the front mold cavity, opening thickness of the rear mold cavity, and

opening thickness of the parting line;

Copper male: front mold copper male, rear mold copper male, parting line clear angle copper male;

Wire cutting: Insert parting line, copper male, inclined top pillow position;

Computer gong: precision gong parting line, precision gong rear mold core;

Electric spark: front mold coarse, copper male, Electronic digital product mold, rear mold bone position, pillow position;

Drill holes, pinholes, and thimbles;

Line position, line position voltage pole;

Plastic shell mold;

Compound thimble, with thimble;

General steps in plastic mold design

1. Process analysis of plastic parts

2. Determine the selection of molding equipment and molding process procedures

3. Analysis of Injection Molding Process and Structural Design of Injection Mold

4. Calculation of dimensions related to plastic mold design

About Us

Zhejiang Industrial Group Co., Ltd. is located in China (Zhoushan) National Pelagic Fishery Base, a large state-owned joint venture by Zhejiang Shenghaida Co., Ltd. (the former Zhoushan No.2 Oceanic Fishing Industry Co., Ltd.) and Maruha Nichir

Zhejiang Industrial Group Co., Ltd. is located in China (Zhoushan) National Pelagic Fishery Base, a large state-owned joint venture by Zhejiang Shenghaida Co., Ltd. (the former Zhoushan No.2 Oceanic Fishing Industry Co., Ltd.) and Maruha Nichir Zhejiang Industrial Group Co., Ltd. is located in China (Zhoushan) National Pelagic Fishery Base, a large state-owned joint venture ......