Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

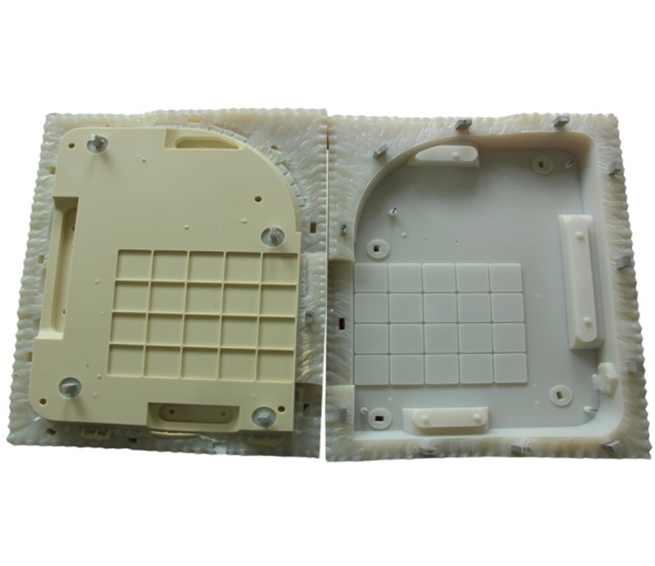

Injection pressure, injection time, and holding time can affect the orientation of molecules. And orientation can affect the crystallization of molecules, so shortening the injection and pressure holding time and reducing pressure can improve its transparency to a certain extent without affecting the performance and appearance of the product.Plastic shell mold--Electronic Digital Product Mold,Plastic Shell Mold for electronic products,Electronic product mold,electronic shell Plastic Injection Mold, plastic injection mould.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.